BioEthanol Production

Process modeling and simulation with ProSimPlus

|

|

|

Simulation results

The calculation sequence (order of calculation of the unit operations) is automatically generated. No initialization is required to converge the flowsheet (no tear stream initialized). Although there are two recycle streams and three specifications, convergence of the flowsheet is easily reached.

Three input flowrates are adjusted in order to reach the right operating conditions for the hydrolysis reactions. 6.7 T/h of LP Steam and 38.2 T/h of HP Steam are needed to reach the working temperature level in the hydrolysis reactor. 2.9 T/h of pure H2SO4 is needed to reach the working acid mass-fraction in the hydrolysis reactor.

To have a recovery ratio de 99.8% of CO2 in the scrubber, a water flowrate of 41.7 T/h is required.

The production is about 22.8 T/h of ethanol on dry basis (99.8% mass) for a feedstock of 71.6 T/h on dry basis (39% mass moisture).

Mass and energy balance on the main streams are available in the full example document.

Column profiles

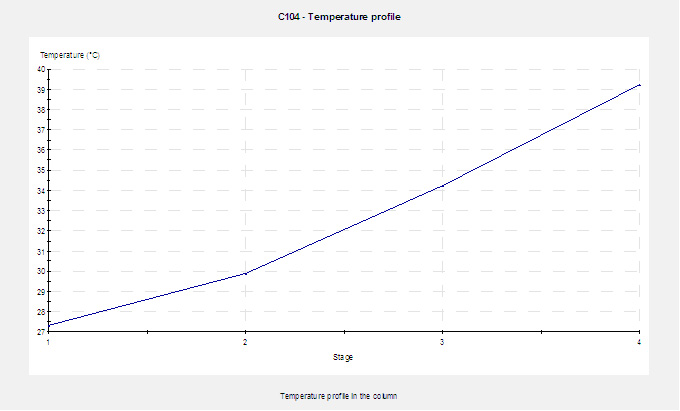

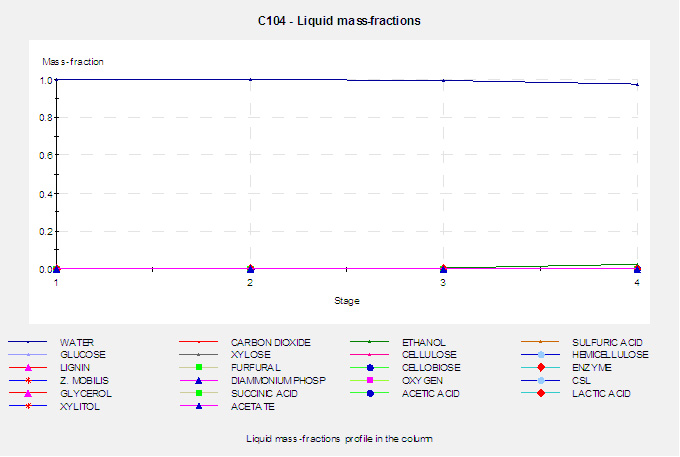

Composition profiles can be accessed after the simulation in each column configuration window, in the “Profiles” tab. Double clicking on the profile will generate the corresponding graph.

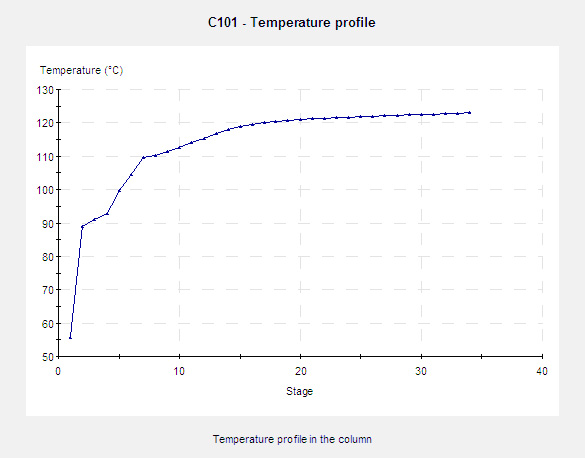

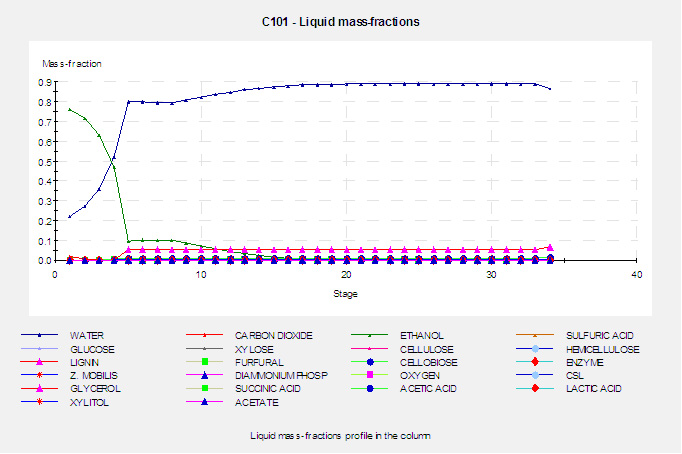

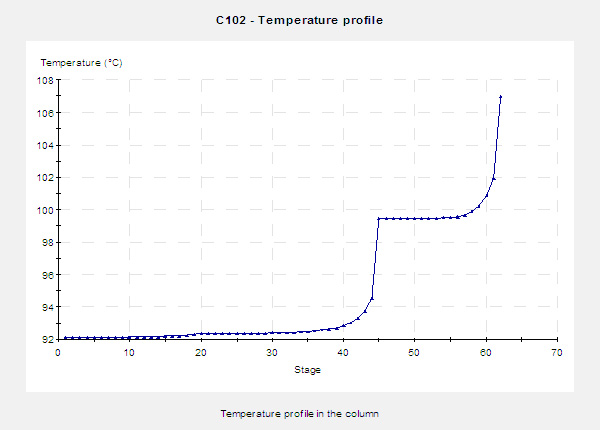

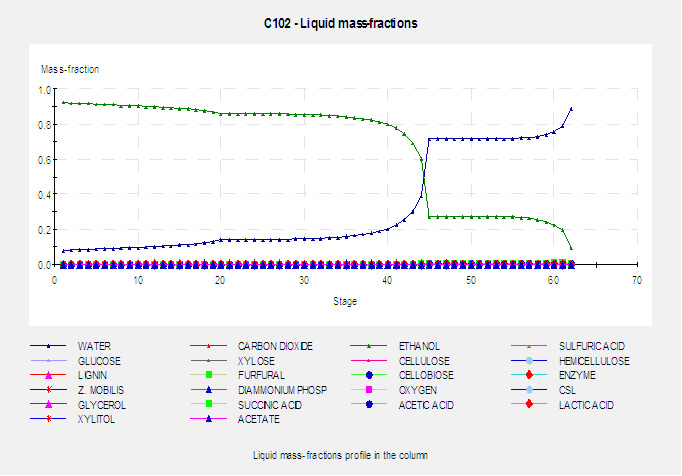

It is important to note that, in ProSimPlus the first stage corresponds to a condenser and the last stage to a reboiler (numbering from top to bottom).

|

| Column C101 |

Temperature profile |

Liquid mass-fractions |

| Column C102 |

Temperature profile |

Liquid mass-fractions |

| Column C104 |

Temperature profile |

Liquid mass-fractions |

|

ADDITIONAL INFORMATION

Contact ProSim by e-mail (sales @ prosim.net) or through the contact page from ProSim website (click on the button):

|

|

|

|

|

|